Latest Contributions

Read More Contributions

My first job at Rourkela and India’s Five Year Plans

Category:

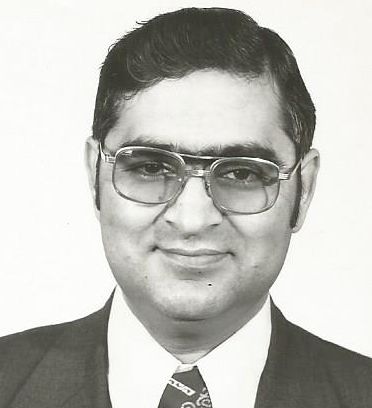

Satinder Mullick received his doctorate from Johns Hopkins University in 1965 in Operations Research and Industrial Engineering, with a minor in Economics. He was Director of Economic Planning and Research for Corning Inc., where he worked on different consulting assignments for improving growth and profitability for 30 years. Later, he helped turn around Artistic Greetings (40% owned by American Greetings) and doubled the stock price in four years. He received Lybrand Silver Medal in 1971 from Institute of Management Accountants.

I graduated from Banaras Engineering College in June 1958. In August 1958, I got a job with Larsen &\; Toubro for the construction of Rourkela Steel Plant.

Off I went from Delhi to Rourkela via Calcutta (now Kolkatta). It was over 900 miles, and took me 36 hours because I had to change trains in Calcutta. I arrived on Sunday. Then, I went straight to my Chief Engineer's house as I needed a place to live and eat, because Rourkela had not developed much. The Chief Engineer, Mr B D Malani, told his driver to take me to L&\;T quarters. It was a house with where the cook used one room to feed us and sleep. There were three others employees, who had come a few days earlier from Bombay (now Mumbai). One was the L&\;T Headquarters accountant, a second was the Rolling Mills accountant, and the third was in charge of Erections of Steel girders.

We got along well as all of us knew that there is no entertainment in this town except work and drink. Since I did not drink local booze or even brand names whiskey, I had to pretend that I am enjoying my soda and lime.

We worked seven days a week - eight hours per day. After that, we had plenty of spare time as no one could sleep more than eight hours in hot weather. Even getting music on a radio was difficult in Rourkela.

Now that was not true of our main contractors - the Germans. Their Club house was built before they arrived, and they had all the amenities, like swimming pool, bar-restaurant, game room etc. For bigger entertainment, they took time off for R&\;R in Calcutta paid by their employers.

Mr (Herr) Koppers was the leader of Krupp Steel for the Rourkela project. Mr Koppers was basically in charge of construction as the German contractor. L&\;T was the sub-contractor, supplying labor to do the construction. Mr Koppers was overseeing construction work of the rolling mills steel structure with moving crane to lift-move heavy hot or cold stuff.

I heard Mr Koppers was lonely in Rourkela. After work, he went to the German Club and drank beer for six hours. And, then to bed. There were a few German ladies in Rourkela-I tried to take German classes from one of them.

My first assignment was to finish riveting of structural girders, beams etc., as new rolling mills will be placed underneath to produce steel. I had roughly 60- 80 people working for me. I was assisted by an Indian supervisor, who himself was a riveter. I was supervised by Germans and one Indian manager.

My day started with Germans yelling their abuses in German as to why so and so is not riveting. They wanted all gangs to make big sounds within 10-15 minutes after the start of work. To them, riveting sounds meant people are working and not goofing off.

In my first week, I was very sensitive to receiving those cuss-words that I complained to Mr Malani. He calmed me down, saying, "Satinder, do you think we would have had World War II without hot tempered Germans?". He said, "Listen to the curse words from one ear and let them out through the second ear."

So, I learnt a trick which was not efficient from Industrial Engineering efficiency point of view, but saved me from curse words. The trick was to shift scaffolding before the shift was over. So, the gang will start riveting within 15 minutes after rivets are hot and start making sounds next morning.

My workers liked me very much. When other workers were protesting for better things and put a big rope to block entry to work, I approached my own staff and asked them if they had any grievances. They replied, "No, Sir." So, I asked them to start their work and tell others to negotiate their grievances without work stoppage. It worked. The work stoppage was discontinued as I promised to help them with my superiors.

Then, the monsoon rains came. One day, it was pouring. I told my staff that no one would climb the girders as mud and water makes it very slippery. If I am scared of my life, then how can I ask them to risk their lives?

But unknown to me, a German told one of my gangs out of 12 gangs (gang has 5 persons, one riveter, one heating person, one passing hot rivet, one getting coal and one to push hot rivet through the hole from the other side for riveter to complete riveting with his gun) to go up and bring back the expensive riveting guns. The gang leader obliged. One worker slipped from top of girder and fell on the concrete block, killing him instantaneously.

Well, now, this could have started a lot of trouble as workers wanted to hit the German supervisor. Confronted with it, I decided it best to send this German supervisor to Calcutta. Then I took charge of the situation, and asked all my workers to come with me to their huts. Since it was raining heavily, I decided to convince the workers to cremate him before sunset today rather waiting for his family for 2-3 days. I knew anger could get out of hand.

Fortunately, my workers agreed. But the problem was that there was no covered cremation facility in Rourkela at that time. So, we decided to cremate while rain is falling. Ghee would not help light the fire, so we agreed to add kerosene and that helped light fire to the wooden pyre.

After the cremation, we came back to the huts around 7 PM. Now I had not eaten anything from 8 AM to 7 PM, and perhaps most of my workers. So, I arranged food for them, and ate with them. I was fully drenched with water. I came back around 10 PM to my house, and asked for a peg of Whiskey for the first time as I was sure that I might be sick otherwise.

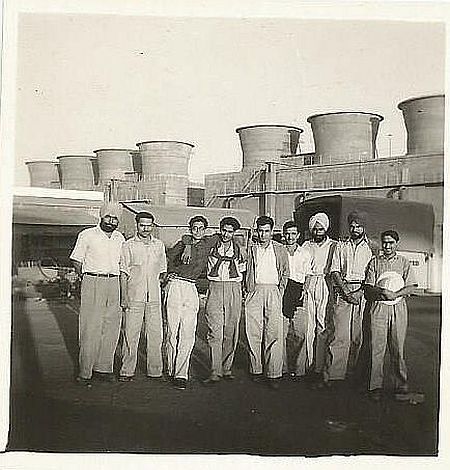

Rourkela engineers. Near the blast furnaces.

Satinder: extreme right holding a helmet\; Shivdasani: in the middle with sweater around his neck.

Around October-November,1959.

Later on, most of riveting work was finished. I was transferred to the third blast furnace. One day, I was told that Mr. Krupp is coming and I must finish the work on the Lift. I have written Lift in bold letters this allowed you to go up easily on the Blast Furnace. Without the lift, we used ladders, which were cumbersome for President of Krupp Steel or our Chief Engineer.

Our Chief Engineer wanted to prove that the third blast furnace work is finished and so Germans must authorize for us to get our payments. Finishing work on the Lift meant working 24 hours per day for five days. I asked my Chief Engineer, "Why are we are rushing when the first and second blast furnaces are sitting idle?" His response was, "That is the Government of India's responsibility, not mine. I am not in charge of the whole project."

I learnt that Delhi planned the project, but somehow there was poor planning for procurement of rolling mills from Austria. According to the plan, hot iron will go directly to rolling mills, where it will be converted into steel, and steel slabs would be produced. Since Austria could not supply equipment (LD Converter) for two years, the blast furnaces could not be fired.

I talked to a few good engineers who told me that the Indian government should have allowed extra money to buy Pig Casting machines to produce Pig Iron for foundries. Pig iron was in short supply.

Well, statisticians in Delhi don't understand the word "Flexibility" and don't understand that in life, you have to give the local Managing Director (MD) discretion to alter the plan somewhat.

I calculated that the "payback for a Pig Casting machine was only three months." In other words, the local MD could buy these machines and use first and second blast furnaces to make lots of money. Then, throw or resell Pig Casting machines when rolling mills were ready. Also, Rourkela Steel Plant had trained engineers and worker sitting idle and getting paid for doing nothing for 2 years. They could be utilized for making Pig Iron.

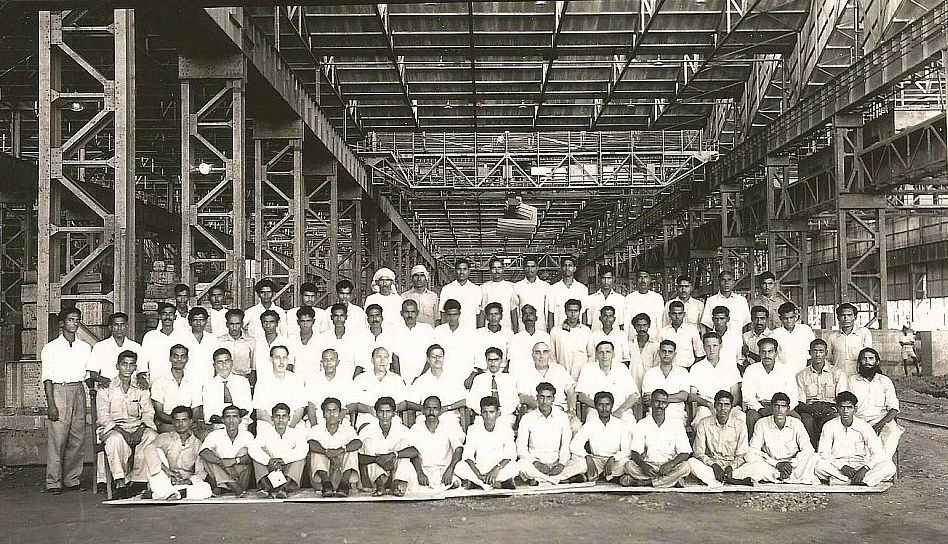

Rourkela send-off party by workers for me.

Satinder, second row in the middle, wearing a necktie. On my right is our Chief Engineer, B D Malani of Larsen &\; Toubro construction division. On my left is Herr Koppers, top man of Krupp Steel for Rourkela. September 1959.

After finishing my assignment on the third blast furnace, I was sent to Delhi to work in L&\;T Dairy division to oversee the construction of Chilling Centers for supplying milk to Delhi Dairy Scheme. In late January 1960, I was sent to L&\;T headquarters in Bombay for dairy equipment sales training.

Luckily, I got a job offer in West Germany from May 1960. This was a nice stepping stone for me to higher education at Johns Hopkins University from September 1961.

Now let us fast forward to 1963, when I was a graduate student at Johns Hopkins University (JHU). My Dean, Professor Robert H Roy, became good friends with P. C. Mahalanobis at an Oxford University conference, where he was a principal speaker after the dinner in September 1957. Mahalanobis was introduced as the "architect "of the Indian Five Year Plans. Couple of days later, Dean Roy invited Mr and Mrs Mahalanobis for dinner after the theater. After a great evening, Dean Roy invited Mahalanobis to JHU someday.

Well that day was in 1963. I was ready with a question based on my experience at Rourkela with the rigidity of central planning. Mahalanobis was very rude to me.

Dean Roy writes in his BRAGOLECTIONS,1990:

"As before, he spoke fluently but his reaction to a pertinent question from our Indian graduate student, Satinder Mullick, was unaccountably and inexcusably rude. Apparently Satinder, who is now Director of Economic Research for Corning Glass was not lofty enough for the great Five Year Planner! "-page 190.

My issue was simple. Plans don't always go with mathematical programming as procurement delays create different Critical Paths, which can be overcome with Flexible Changes at the discretion of local Management with quick review and authorization of money.

Sometimes, you take a journey by car to meet someone by one route, but you encounter a weather related major accident requiring a different route and more expenses. Now if you have the money, you can spend the extra money without asking your company's controller for approval. You concentrate on your mission by spending little bit of extra money.

I remember that J R D Tata wrote an article in Bhavan magazine, after my incident at JHU in 1963, on Five Year Plans. His message was that they are mostly not on target. Laxman made a cartoon-someone hitting darts at the dart board. The message- "Do U think it is India's 5 years plan?"

India wasted lot of money on Government-run big plants. In September 1967, I was travelling from Bombay to Delhi by Indian Airlines. My next seat passenger was Dr. Ansari (not who later became the Vice President - someone else) who was of Nehru's age and knew Nehruji well. We had a conversation about my experience at Rourkela. His reply was," Nehruji wanted to unite Indians by building new temples of large industrial complexes." So, he hired Mahalanobis to be the Chairman of Planning Commission to create 5-year plans like Russians. Next day, I read in Delhi newspapers that Dr. Ansari was appointed governor of Orissa.

Nehruji was mesmerized with Russian planning and decided to build big new projects without realizing that people like J R D Tata or G D Birla, and others, know every day how their projects are proceeding. If there is a problem, a trouble shooter is sent to get the project back to the scheduled date of competition. There is a saying, "Marwari are good, because they tally up accounts daily." The Walmart owner used to get inventory data at 2 AM in the morning, and by 6 AM, he had trucks ready to fill in the stores with items needed on the shelves. This is before online computers algorithms were invented and implemented.

Mahalanobis was great at mathematics and statistics, but he had never worked a day in a plant or in a project. India paid the price, as I can tell you from my experience.

© Satinder Mullick 2017

Add new comment